The Benefits of Visual Inspection Equipment

There may be more recent developments in devices and equipment for inspecting the condition of structures, but the most basic and oldest techniques can still be reliable. Visual inspection. Also known as ‘visual testing’, it is traditionally known as the process of inspecting a particular area with the naked eye to find flaws. However, the process is now aided by visual inspection equipment, which can ensure more accuracy. By using Videoscopes, crack measuring tools, and crack cameras, you can speed up your inspection and deliver precise results to help you make informed decisions for your project.

Visual inspection equipment increases productivity and minimises downtime. It can help reduce expenses from costly rework and mistakes, which can be the result of inaccurate measurements and results. Quality control is another reason to utilise advanced equipment for visual inspections. With the right devices, you are more likely to satisfy your project’s requirements and ensure the safety of the structure. The equipment may even boost the efficiency of, and quality of your work, especially when you want to improve your reputation in the industry.

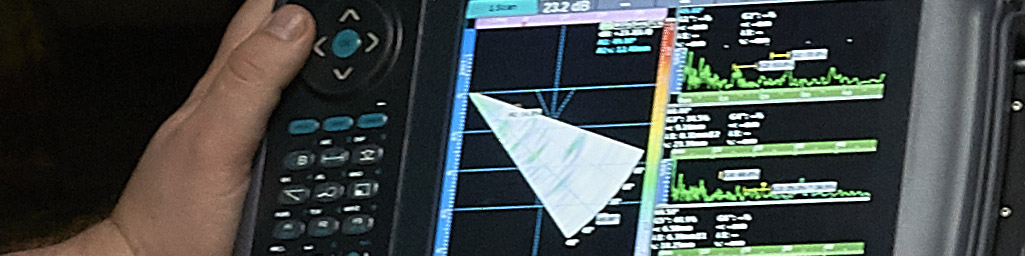

High-quality visual inspection equipment pieces are available from reputable retailers at competitive prices. They come in configurations and sizes so you should be able to find the right product that will suit your project’s requirements. Videoscopes, for instance, allow you to make visual inspections quickly and more accurately when it allows access into hard-to-reach places. They come with LCD monitors and a digital image processor, with video recording capabilities, support for multiple languages, and a joystick controller for flexible probe documentation. A Videoscope can also take snapshots, just be sure it has a high-resolution screen, multiple articulations, and a lengthy probe.

The crack width measuring camera is another type of visual inspection equipment. This time, it combines intelligent measurement and crack detection systems with a close-focus camera for measuring and documenting crack widths in construction projects. With this equipment, you can determine defects of a concrete structure. It is suitable for measuring cracks that are between 0.02mm and 6.5mm wide. Reputable retailers of visual inspection equipment offer other crack measuring tools, such as digital position strain gauge deformation meters. They come complete with a crack magnifier, monitor, and a field microscope, for an all-in-one package that helps you save time, so you can accomplish your inspection faster.

About

PCTE Industrial is a specialist in the sale and hire of industrial non-destructive testing (NDT) equipment. PCTE INDT is a branch of PCTE, who have been serving in the NDT industry since 2008. We offer a range of INDT equipment that covers the bread and butter applications but also adds some exciting technology. Our range covers devices for Ultrasonic Testing (UT), Eddy Current (ET), Magnetic Particle (MT), Dye Penetrant (DT) and Visual Testing (VT).