Equotip Piccolo/Bambino 2

Equotip Piccolo 2

For real-time monitoring and user specific conversions

For real-time monitoring and user specific conversions

Metal heat treatment allows mechanical properties to be changed so that the metal will be harder, stronger and more resistant to impact. The Piccolo 2 is used to monitor and document the strengthening of high integrity metal components for the automobile industry. Automotive Lifting Technology are subject to stringent requirements that need to be met by an automotive lift manufacturer. The portability of the Piccolo 2 is ideal for testing bulky lift components.

Equotip Bambino 2

For quick on-site hardness checks

For quick on-site hardness checks

Scuffing can lead to catastrophic failure in engineering components. E.g. in turbines of power plants where wearable parts are required to endure high mechanical stress. The Bambino 2 with the DL probe can be used to ensure that stressed recesses, joints and edges are of the correct hardness to minimize scuffing. Cold rolling is often used to decrease the thickness of sheet metal. To avoid spall fracture, Equotip and Equotip’s Leeb hardness unit HL are used as a standard for roll testing in rough environments. The light-weight Equotip Bambino 2 lends itself to quick intermittent checks of rolls.

The Differences between Piccolo 2 and Bambino 2

The Equotip Piccolo 2 and Bambino 2 are both suited for on-site hardness checks of metals where the test indentation should be as small as possible. The robust design and large display allow the user to work at dusty worksites with low visibility. Both products also display metal hardness in all common scales.

The Equotip Piccolo 2 offers the same features as the Equotip Bambino 2, but has the following additional features:

1) user defined hardness conversions

2) Piccolink software for:

a) systematic real-time monitoring of hardness

b) automated testing during serial production

c) evaluation and processing of measured data

d) remote controlling of Piccolo 2 settings

Equotip Piccolo 2 and Bambino 2 are supplied with a D impact device. It can be interchanged with an optional DL impact device, which is useful for measurements in restricted areas.

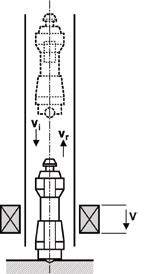

Leeb Rebound Principle of Equotip Hardness Testers

Leeb Rebound Principle of Equotip Hardness Testers

The portable hardness testers used most commonly for metals are based on the Leeb rebound method inventedby Proceq SA. The Equotip Piccolo 2 / Bambino 2 operate according to the Leeb principle, in whichthe hardness value is calculated from comparing the energy of a test body before and after impacting on asample. This Energy QUOtient (EQUO) is quoted in the hardness unit HL and is calculated from comparingthe impact and rebound velocities (vi , vr) of the impact body. It rebounds faster from harder samples thanfrom softer ones, resulting in a greater energy quotient which is defined as 1000·vr/vi.

Immediate Conversion to established Metal Hardness Scales

Metal hardness can be displayed in different hardness scales: HL (Leeb), HRC (Rockwell C), HB (Brinell), HV (Vickers) and so forth. The Equotip Piccolo 2 / Bambino 2 enables measurements to be rapidly taken and displayed in any chosen hardness scale. The Equotip Piccolo 2 has an additional feature that lets the user customize conversion curves for special alloys and also allows the user to convert hardness readings into tensile strength.

Benefits

- Entry model for quick on-site tests

- Compact housing and automatic angle correction allow flexible use

- Comes with the high accuracy known for all Equotip products

Features

Firmware:

- Automatic compensation for impact direction

- Integration in automated testing environments (incl. remote control): Equotip Piccolo 2 only

- Language independent

Software:

- Piccolink software (Equotip Piccolo 2 only)

Display & Memory:

- Monochrome 4-digit display

- 32 KB memory (~ 2’000 readings) (Equotip Piccolo 2 only)

Connections:

- USB interface to PC

Key Accessories

Key Accessories

- Equotip DL Accessory Kit - This is a unique feature offered by Proceq. It allows the user of a Piccolo 2 / Bambino 2 to quickly and easily interchange the D and DL impact devices.

- Test Blocks - It is necessary to regularly conduct 3 to 10 test impacts on a reference hardness object to verify the correct operation of the Equotip device. Various test blocks are available depending on the users’ hardness requirements. For added convenience, the test blocks also indicate the reference hardness value in different hardness scales.

Support Rings - Leeb rebound testers only work correctly when the impact body is held at a proper distance from the test surface during impact. The wide range of support rings permits testing on a great variety of part geometries, i.e. flat surfaces, concave or convex cylindrical surfaces, spherical test surfaces.

Support Rings - Leeb rebound testers only work correctly when the impact body is held at a proper distance from the test surface during impact. The wide range of support rings permits testing on a great variety of part geometries, i.e. flat surfaces, concave or convex cylindrical surfaces, spherical test surfaces.