Automated Scanners

Automated Crawler Scanners are a new generation solution to large scale applications where the shear size, height or circumference create challenges. Using automated crawler scanners removes safety risks for personnel, saves time and money as the need for scaffolding is removed.

Automated Crawler Scanners are a new generation solution to large scale applications where the shear size, height or circumference create challenges. Using automated crawler scanners removes safety risks for personnel, saves time and money as the need for scaffolding is removed.

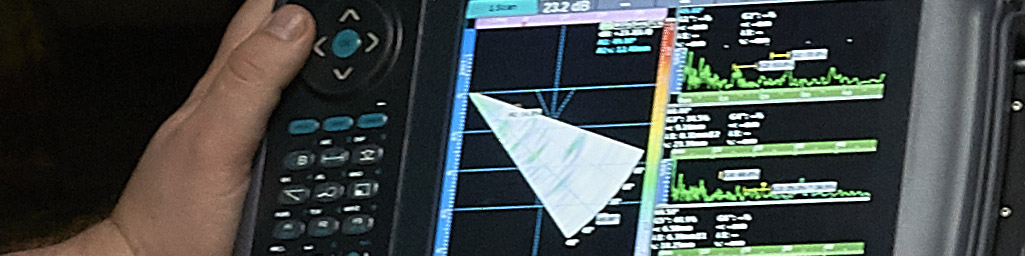

These scanners can simultaneously carry probes and wedges for Phased Array and Time-of-flight-diffraction (TOFD) weld inspection.

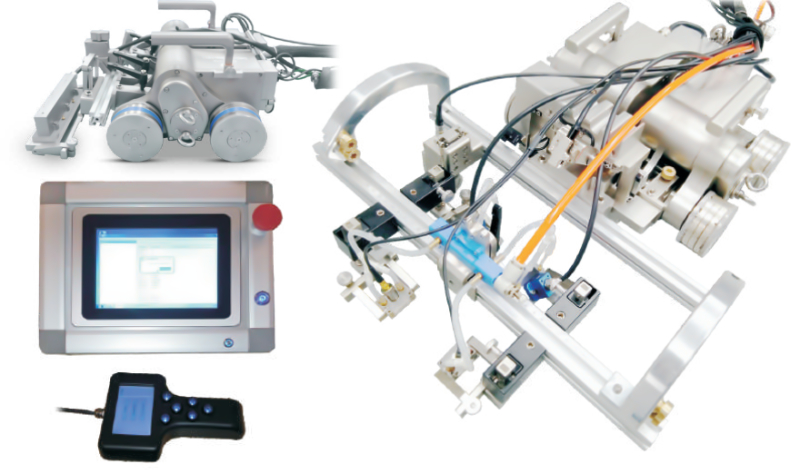

Gecko DSC-03 - Automated Crawler Scanner

Specifications

- Real-time acquisition of working environment images

- Displacement Reciprocating Accuracy Error <=+/1mm

- Speed accuracy error< 5%

- When the wall thickness of bare metal magnetic workpiece in vertical direction is more than 20 mm, it can carry 20KG

- Circumferential motion applicable range 800mm-plane, axial motion applicable range 500mm-plane

- Measuring the Thickness of Workpiece (> 5mm)

- Crawler speed range 20mm/s-120mm/s

- Motion speed of power arm is 10 mm/s-130 mm/s

- Motion control mode:

- Free Motion Model

- Displacement motion mode

- Two-axis scanning mode: raster scanning/sawtooth scanning

Features

- Phone WIFI + wired remote controller

- 360°real time monitoring camera

- Support all orientation movements, with cruise control

- Multi-probe clamp modes, welds compatible

- Base material & corrosion inspections

- Battery working up to 5 hours on-site

Application Field

- Weld Detection of Large Tank

- Flat plate weld detection

- Base Material Testing

- Corrosion detection

- Ultrasound Thickness Measurement

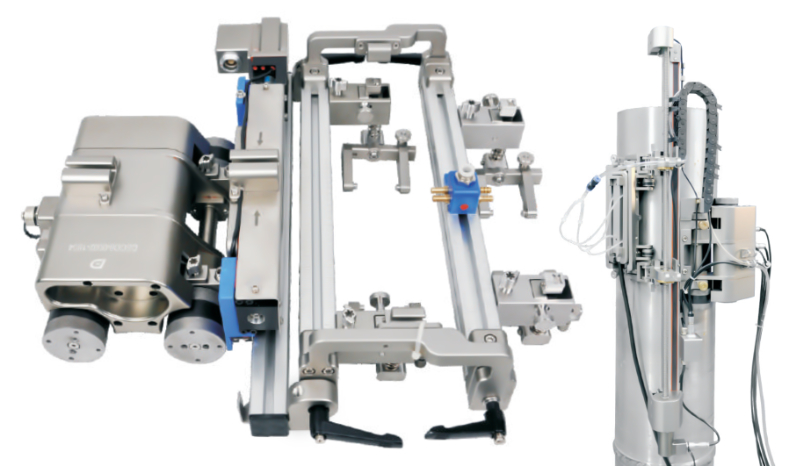

DSC-08 - Multi-function Automated Scanner

As the name implies this is a multi-function scanner used for large pipe inspections or plate welds where manual scanning would be too laborious and time consuming with the risk of missing data or defects.

As the name implies this is a multi-function scanner used for large pipe inspections or plate welds where manual scanning would be too laborious and time consuming with the risk of missing data or defects.

Complicated inspections can be carried out quickly especially when the window of opportunity for the inspection is restricted.

The DSC-08 Multi-functional automatic crawler is suitable for pipes which OD are greater than 152mm, or plate welding. 64 or 128 element water column probes are optional to perform corrosion / basic material inspection.

32-16 element probes are optional to perform girth welding two-sided inspection. Remote control available to move forward and backward, as well as to control the guide screw to move to left and right(500mm).

| DSC-08 | |

| Circumferential motion | 152.4mm-flat |

| Encoder Step | 28.3 pulses/mm |

| IP Level | IP65 |

| Storage Temperature | -20°C- +60°C |

| Operating Temperature | -10°C- +50°C |

| Maximum speed | 39 mm/s |

| Minimum speed | 8 mm/s |

| Maximum load on the vertical plane | 6kg |

| Axial motion | Φ1500mm-flat |